Ma On Shan Mine – Part Two, Going Underground

Tymon Mellor: Introduction

The Ma On Shan Mine was developed using open cast excavation as the primary means to extract the iron ore following the initial find in 1905 to the early 1950’s. As part of the Japanese managed mine modernisation, mineral extraction went underground with the use of mining techniques. This had a twofold effect, reducing labour requirements, and boosting productivity. The mine had a future.

This article will discuss the now abandoned underground workings of the Ma On Shan Mine. The shafts, tunnels and adits have not be maintained in nearly 50 years and their condition is unknown. These workings should not be entered as they may be unsafe.

Underground Excavation

The use of tunnels for excavation underground at Ma On Shan was first recorded by Weld in 1914, with adits excavated to establish the edge of the ore bearing material. In the 1950’s, short tunnels were also excavated to extract minerals for the less productive areas and to explore for new outcrops. These tunnels can still be seen along the mine access road.

Underground Approach

In 1953, the Japanese mining company Nittetsu Mining Company started providing technical support and financial investment for the mine. There were several issues to address, including the stability of the slopes around the open cut workings, the poor quality of the ore, and the outdated working practices.

The initial plan was to establish a state of the art ore dressing plant at the coast, above what is now the new town of Ma On Shan, to increase the iron content from the natural 30-32% to around 60%, making the ore a more attractive commodity. A new supply contract was negotiated with Nippon Steel for 120,000 tonnes of ore a year.

The dressing plant was erected at an elevation of 110m, known as the 110 level, and began operation in October, 1954.

The plant operated 24 hours-a-day, producing 480 tons of iron concentrates (60 percent) from every 500 to 700 tons of raw ore extracted. The raw ore was delivered to the plant in modified ex-military trucks, down the steep road from higher working levels.

The open cut workings consisted of the original area at the 240 level and then later in an area at the 280 level. As the ore body moved into the hillside, open cut excavation became slower and more susceptible to landslides. The first mining adits commenced in early March 1953 with an initial 3m drive. These first drives were driven from the 280 level, at was known as Adit A. Further adits were driven into the ore body primarily from the 240 level, with Adit D forming the main entrance to the mine. By July 1955, the total length of the underground mining tunnel had reached 3,139 m, and the underground works supplied much of the ore for the dressing plant. However, during the transition period from open cut to underground, low grade ore from the open cast tailings was used to maintain production of the dressing plant.

By 1959, the open cut works were abandoned and all ore extraction came from the 240 level underground workings.

Starting at the 240 level, the miners excavated adits and cross adits into the ore body, and extracted the ore using the mining method known as ‘sub-level stoping’, involving the excavation of the rock in a series of vertical shafts or stopes, with the rock being blasted from the roof of the stope and using gravity to drop it into shoots for extraction. The ore was then loaded on to narrow gauge cars and removed to the surface for transportation to the dressing plant.

Mining started at the 240 level and proceeded up, with new levels at 247, 254, 261 and 268. By 1960, the levels above 240 were producing over 150,000 tons a year, before they were exhausted by 1965.

Landslides continued to occur in the open pit areas, particularly after heavy rain, blocking the mine access. As can be seen from the above images of the Adit D entrance, this had to be modified on multiple occasions to maintain production.

During the late 1950s, extensive ground investigation was undertaken by the Japanese engineers to identify the extent of the ore body. By drilling long holes into the mountain, the engineers confirmed that the ore continued deep underground and extended further into the hillside of Ma On Shan. The only way to extract the mineral was to develop a new deeper underground mine with an access that avoided the landslide prone slopes.

With the new survey information, the company was able to revise the estimated ore reserves (as published in 1961) as shown below, and to make the necessary financial investment.

| Level | Reserves | Fe% | Extraction % | Workable |

| 240 – 200 m | 3,250,000 t | 34.71 | 60 | 1,950,000 t |

| 200 – 180 m | 864,000 | 34.71 | 60 | 518,000 |

| 180 – 160 m | 343,000 | 31.25 | 60 | 206,000 |

| 160 – 110 m | 94,000 | 29.29 | 60 | 56,000 |

| Total | 4,551,000 | 34.34 | 60 | 2,730,000 |

The plan was to drive a new 2,160m long tunnel from the dressing plant, at the 110 level into the ore body. This tunnel would be used for ore extraction. Working levels would be established with the existing 240m and new levels at 192m and 144m with an inclined ramp access from a new 240m level adit portal. Within the mine, the ore would be excavated using the sub-level stoping method, requiring the driving of 3,000m of tunnel, 2m wide and 2m tall each year. Vertical ore shafts or ore passes were provided to transfer the blasted rock from the production level to the ore hoppers at the 110m level, and thence transportation to the processing plant.

This expanded arrangement required investment in new tunnels and new equipment at a cost of more than HK$ 3 million (1960 prices). The design of the mine was optimised to gravity where possible, to move the ore, reducing production costs while improving efficiency.

Tunnelling for the 110 adit commenced in June 1961 and was completed by 1963. The excavation required over 50,000 kilograms of explosives to blast out the 17,000 m3 of granite.

While the adit was under-construction, a new portal was established at the 240 level, clear of any potential landslides, and a 26° ramp driven down to the 144 level to connect with a 30° ramp down to the 110 level. Production from the new workings commenced in 1960 with the ore being hauled up the ramps and out at the 240 level until August 1963 when the 110 level was commissioned.

Mine Production

In 1963, with the completion of the 110 level tunnel and the improved means to transport ore, production improved and by the second year, 1964, the crude ore production increased sharply to 250,000 tons, and the following year in 1965 to 270,000 tons. Details of the total Hong Kong mineral production in the post war years are shown below. The iron ore was produced from Ma On Shan.

| Year | Iron Ore | Clay | Feldspare | Quartz | Graphite |

| 1948 | 923 | 3,936 | |||

| 1949 | 60,131 | ||||

| 1950 | 172,092 | ||||

| 1951 | 163,263 | 630 | |||

| 1952 | 129,559 | 4,451 | |||

| 1953 | 125,177 | 6,029 | 203 | ||

| 1954 | 92,257 | 6,150 | 1,871 | ||

| 1955 | 117,354 | 5,519 | 703 | 1,562 | |

| 1956 | 124,937 | 5,552 | 3,053 | 2,480 | |

| 1957 | 95,694 | 7,073 | 1,175 | 4,529 | 3,358 |

| 1958 | 106,812 | 7,743 | 1,680 | 4,559 | 1,965 |

| 1959 | 121,817 | 7,372 | 1,744 | 3,628 | 1,965 |

| 1960 | 118,921 | 6,770 | 2,551 | 3,873 | 2,666 |

| 1961 | 119,248 | 8,565 | 1,225 | 4,110 | 1,227 |

| 1962 | 113,327 | 6,478 | 952 | 4,223 | 357 |

| 1963 | 113,660 | 5,100 | 1,707 | 3,045 | 546 |

| 1964 | 116,210 | 5,124 | 1,581 | 1,675 | 627 |

| 1965 | 134,073 | 4,788 | 1,140 | 1,940 | |

| 1966 | 136,948 | 5,864 | 1,365 | 2,743 | |

| 1967 | 143,619 | 8,570 | 1,153 | 3,048 | 3 |

| 1968 | 161,594 | 5,665 | 1,607 | 3,694 | 302 |

| 1969 | 165,946 | 4,411 | 1,904 | 6,318 | 19 |

| 1970 | 170,256 | 3,784 | 1,621 | 5,350 | |

| 1971 | 162,739 | 2,540 | 1,145 | 5,141 | |

| 1972 | 162,283 | 3,162 | 1,149 | 3,631 | |

| 1973 | 150,713 | 3,753 | 1,340 | 991 | |

| 1974 | 159,737 | 3,320 | 5,566 | 351 | |

| 1975 | 167,200 | 1,490 | 2,059 | 761 | |

| 1976 | 37,058 | 1,305 | 2,299 | 982 | |

| Total | 3,643,548 | 135,144 | 38,719 | 64,592 | 19,151 |

Source: Hong Kong Economic and Trade Statistics (1947-1987)

Underground Workings

The miners would enter the underground environment from the 240 level, travelling down the ramp on a cable hauled railway. Then reaching working levels they would start their day. Teams would drill the ore bearing rock for the daily blast, others would clean up and undertake secondary blasting to break-up oversized boulders.

The blasted ore would feed discharge chutes or draw points where the material would be loaded into hand pushed cars or a four-ton battery locomotive pushing 1m3 muck skips. Through a series of vertical passes, the ore would be dropped to the 144 level where it was further dropped to the 110 level and into the hoppers.

In addition to men moving the ore with chutes and shovels, the mine was also equipped with a scraper system. Ore from the stopes descended to the draw points where a scraper pulled past, collecting the material and dropping it into an adjacent ore pass. With this arrangement, one man could clear four draw points with minimal resources. The winch foundation and protection wall, in case of a snapped cable can be seen in the image below.

110 Level Transportation

At the 110 level, the ore was stored in the vertical ore bins and loaded into 2.3 m3 mine-cars using mechanical chutes at the bottom of the vertical shafts. The mine cars were of a Gramby Type, providing the ability to be automatically emptied, by opening one side, once they reached the surface ore bin.

An 8T electric locomotive, powered from a DC overhead line would then shuttle between the loading chutes and the surface dressing plant pulling 12-15 mine cars.

The miners would spend the entire shift underground, so facilities were provided for the serving of food, storage of equipment and explosives. The workers had to make their own toilet arrangements however! The mine worked a two shift arrangement, necessary to support the dressing plant.

A team of 15 miners would drill the face using air drills, before handing the area over to the blasting team. Each blast took three days to prepare, taking care to avoid short circuits through the conductive mineral rock. Following the blast, the gasses were left to clear before an inspection was made of the blast. Secondary blasting would be undertaken where oversized material was found at the end of the shift, ready for the second shift to clear.

At the 110-surface platform, tracks were laid to a balance station to weigh the cars before they were emptied. Tracks were also laid to allow for the trains to access a marshalling yard and to be maintained. From the balance station, a 60m long steel bridge was erected across the mine access road to allow the ore train to pass and dump the ore into the ore bin of the dressing plant. The ore cars were drawn slowly past the ore bin and with the aid of a tipping guide rail, the cars opened sideways to deposit ore in the ore bin.

When the train had discharged the ore, it returned to the double-track yard by driving backwards and then the locomotive would be transferred to the front of the train before returning in the 110 level adit.

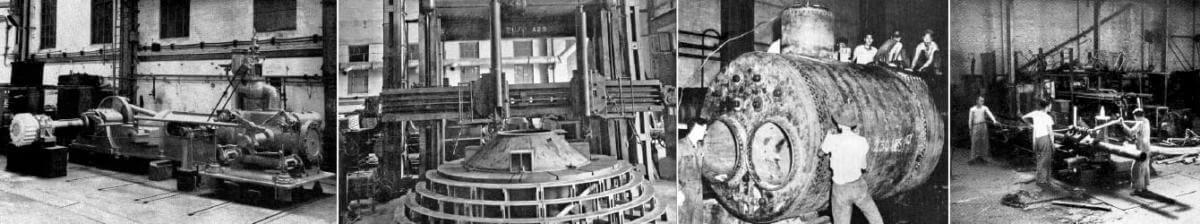

Ore Dressing Plant

A new era for the mine began on the 1st November 1954, when a fully-mechanized ore-dressing plant was commissioned. Work on the plant began in mid-March and was completed by October, 1954. A big opening ceremony was held, officiated by the Minister of Labour and Mines.

The plant was designed to screen out iron mineral from minerals with no commercial value, improving the quality of the ore ready for export. At the time of its installation in 1954, the plant was situated only about 200 m away from the coastline, before land reclamation took place in the 1980s.

Initially, the ore was supplied by truck from the surface workings, but with the commissioning of the 110 level in 1963, all raw ore was delivered by train.

The plant was one of the most advanced of its kind in Asia at that time. It was installed by the Nittetsu Mining Company of Japan for the Mutual Trust Co. Ltd. on a rental basis. The construction cost of the plant was HK$1 million (1953 prices) and the ore-dressing plant was operated day and night producing 480 tons of iron concentrates (60 percent) from every 500 to 700 tons of raw ore.

In addition to the plant, a new power supply and substation was required, costing another HK$650,000. This included installing a new transmission line halfway across the New Territories and laying a marine cable under Tolo Harbour sea bed.

The plant required 1,360 m3 of water each day and catchwaters of 350m and 2,100m were constructed to transport water from a hill stream to fill a 250m3 concrete water tank which supplied water to the plant.

The plant adopted three-stages of processing where the raw ore passed through crushers, then underwent grinding before desiccating, after which the ore was taken by conveyor belt to the stock pile ready for shipment to Japan. Details of each of these stages are described below.

Crushing Section

At the plant, the raw ore was initially poured into an Ore Bin from which it was carried to the Blake Crusher. There, the ore was crushed to 75 mm, and was then delivered to the Gyratory Crusher from which the output size was reduced below 50 mm. In the Cone Crusher,the ore was further crushed to 14 mm or below, which was the required size of the feed-ore entering the Mill Bin.

Grinding Section

From the Mill Bin, the feed-ore was carried by an Apron Conveyor to the Conical Ball Mill in which the ore was mixed with water and ground to fine ore pulp (65 mesh). The fine pulp emerged from the Ball Mill to enter the Rake Classifier where the coarser pulp (+ 65 mesh) would be removed back to the Ball Mill to be ground again. The finer pulp (-65 mesh) was pushed into three sets of Wet Magnetic Separators where it was separated into “iron concentrates”, “middling” and “tailing”. The tailing was disposed to the sea while the middling was pumped back to the Separators to be concentrated again. The iron concentrates containing about 54 percent iron content, were allowed to enter the Dry Magnetic Separators where their iron content was raised to 57 percent.

Desiccating Section

The iron concentrates coming from the Magnetic Separators were de-magnetized before they settled at the bottom of a big circulator tank called the Thickener. From the Thickener, they were directed by a pipe to a Dorrco Filter where they were desiccated. The dry concentrates which still contained 9 percent of water passed through an Automatic Conveyor Scale where they were weighed before they were collected in stockpiles ready for export to Japan.

From the stockpiles, the iron concentrates would be taken away by motor vehicles and then loaded onto the barges which tied up alongside a jetty in Tolo Harbour. From the barges, the iron concentrates were loaded onto ocean-going ships anchored in Tolo Harbour, and shipped to Japan.

Recovery Plant

Back in the early days of the processing plant, the old tailings of the open cast working were used to make up shortfall in raw ore for the processing plant. It was clear that the low-grade tailings still contained much iron. Therefore, in early 1960 a second plant was established at the 200 level, at a location close to the old open works tailings. The plant was not as sophisticated as the main plant, providing only preliminary treatment of the low-grade ore. This included crushing, screening and dry magnetic separation before the mineral concentrate was passed on to the main plant for final dressing. The plant was supported by a 700m catchwater located on the 200m contour level.

Closure

With a fall in ore prices, as a result of the opening of the big open cast mines in Australia and decline in demand due to a world-wide recession in the early 1970’s, the ore was no longer competitive. The mine was closed in March 1976 and the workforce of 400 was laid off and the mining lease expired in March 1981.

The dressing equipment was removed and the entrances boarded off. All the entrances to the levels above 240 were lost to landslides, leaving only the 240 level and 110 level serving the main body of the mine.

In March 2016, the remaining surface facilities were given a Grade II listing by the Antiquities Advisory Board with discussion on protecting the underground mine workings.

From 1949 to 1976, when the mine closed, the mine produced about 3 million tons of iron ore for export to Japan. According to the prospecting reserves, there are still about 4 million tons of iron ore left untapped in the mining area. This may seem a lot, but according to the reserves of iron ore deposit classification, the world’s large and medium iron ore mines have reserves of more than 10 billion tons. Ma On Shan does not have the resources to be competitive.

When you next see, a Japanese product made in the last quarter of the twentieth century, if it contains steel, it may have originated from Ma On Shan.

Sources

- Notes on an iron-ore deposit near Hong-Kong, China, by C.M. Weld, 1914 https://babel.hathitrust.org/cgi/pt?id=osu.32435008239741;view=2up;seq=1

- http://mos.hk/maonshan/2/9/10

- http://mos.hk/maonshan/4/31/63

- http://mos.hk/book_onshan/newpart1a.htm

- http://mos.hk/book_onshan/newpart1b.htm

- Development Plan of Ma On Shan Iron Mine, New Territories, Hong Kong, Taketo Shibata, Economic Geology of Hong Kong, 1964

- Hong Kong Annual Report 1955

- Hong Kong Annual Report 1960

- Historic Building Appraisal, Exterior Wall of 240 ML (1953), Mineral Preparation Plant (1954 & 1963), Exterior wall of 110 L (1963), Ma On Shan Mine, Sha Tin, N.T.

- https://www.facebook.com/media/set/?set=a.149724028383660.26571.141742272515169&type=3

- Historic Maps www.hkmaps.

- The Geology and Exploitation of The Ma On Shan Magnetite Deposit, P J Strange and N W Woods, Geological Society of Hong Kong Newsletter Vol 9 No 1 p3-15 1991, http://www.geolsoc.org.hk/newsletters.htm

This article was first posted on 17th April 2017.

Related Indhhk articles:

- Ma On Shan Mine – Part One, The Open Cut Years

- Mine – Ma On Shan Iron

- Mine – Ma On Shan Iron, 1906-1976, open-pit and underground mining

- Mine – Ma On Shan Iron, Hong Kong Naturalist, 1931

- Mine – Ma On Shan, Kuhn Mines Ltd, railway(s) at MOS mine

- Mine – Ma On Shan, recent damage caused to explosives storeroom

- Mine – Ma On Shan, recent underground images

- Mine – Ma On Shan – SMP article, nearby miner’s village, three buildings restored

- Mine – Ma On Shan – underground film, 2014

Hi Tymon

Great article, I visited the mine a while back but didn’t exit the 110 level as I thought it was flooded!

I noticed recent photos showing new metal gates, have they since sealed the entrance?

Hoping to visit again soon and complete the exit from the 110 entrance!