Hong Kong Water Supply – The Tai Tam Tuk Scheme – Second Section

Tymon Mellor: In 1902 the Public Works Department embarked on the Tai Tam Tuk Scheme. This was divided into the First Section covering the construction of the Tai Tam Intermediate Reservoir and the Second Section for the main Tai Tam Tuk reservoir. The latter would become Hong Kong’s largest reservoir with a capacity greater than the total of all the other reservoirs combined. Even with the new storage capacity, it was recognised that this would only address existing water shortages for the following 15 years.

Tai Tam Tuk Scheme Delays

With the completion of the site investigation for the dam sites at the end of 1904, the two estuary sites were rejected due to the depth of the bed-rock, and the preferred location was sited just below the village of Tai Tam Tuk at the head of the river estuary. Work commenced on preparing the design and tender documents for the new dam, but due to financial constraints[i], the project was suspended in 1907.

The dam consisted of a concrete retaining structure, clad with granite stone blocks, spanning across the existing valley. A temporary diversion channel was required on one side of the dam to allow the existing river to be diverted and the foundation of the dam to be constructed. The new reservoir would capture water from the surrounding catchment area and enlarged with catchwaters. The water from the dam would be transferred by water main to a pumping station where the water would be pumped up the hill to the existing water supply culvert.

By 1909, two years after the completion of the Tai Tam Intermediate Reservoir, a low summer rainfall resulted in the re-introduction of intermittent water supply through the use of the rider main systems. By 1911, the water shortages were so acute that the temporary pumping arrangement previously utilised down-stream of the dams was once more re-installed to supplement the supply, pumping 70 million gallons by the end of the year. This would remain in operation until November 1915 when it was de-commissioned with the impounding of the new dam.

The scheme required the construction of the new dam, extension of the existing pumping station and construction of new pumping and supply mains.

Tai Tam Tuk Scheme – Second Section

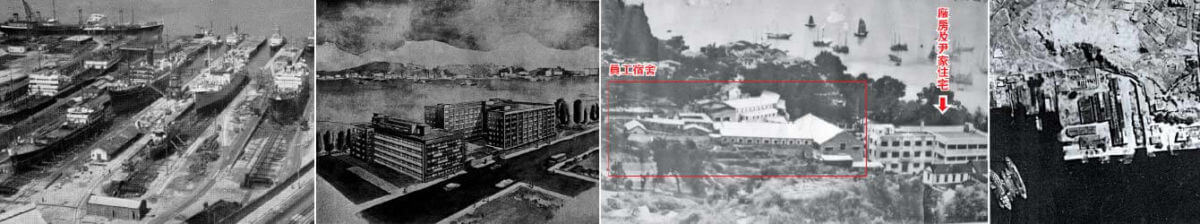

In 1912 with the results of the site investigation and confirmation of the water supply from water gauging observations it was decided to construct a new dam below the village of Tytam Tuk. This reservoir would have a capacity of 1,500 million gallons and would cost an estimated $2,017,000 to construct. On the 24th October, 1912[ii] a contract was awarded to Messrs Sang Lee & Co for the construction works. Work commenced immediately, with the provision of accommodation for 400 workers and excavation for the main dam commencing on the 7th December, 1912[iii].

Construction of the scheme was supervised by Mr Jaffe assisted by Mr Henderson and Mr Newhouse along with a team of site staff all operating out of a dedicated stone site office.

During 1913 excavation for the dam foundations continued along with the diversion of the stream allowing the casting of the initial foundation concrete on the 24th December, 1913. Quarrying for dam stone commenced at ‘Totiwan’ along wih the diversion of the Shaukiwan to Stanley Road necessitated by the works. To allow construction of the dam foundation in the former stream bed, a cofferdam was constructed to prevent flood water and sea water ingress. The first consignment of 246 tons of 450mm cast iron mains were delivered.

Good progress was made during 1914 with the focus on the excavation of the soft material of the old river valley. A sheet pile cofferdam was completed in March allowing excavation to the rock head to be undertaken with the provision of multiple pumps to stem the water inflow. As forecast, the rock head was encountered at 9m below the original stream bed where concrete for the dam foundation could commence.

Two large culverts, 3.6m wide and 3m high were constructed to take the diverted stream flow while the dam was under construction. The river flow was diverted into the culverts in March, 1914 allowing completion of the cofferdam across the original stream path.

The remaining cast-iron pipes were delivered for the new suction and twin delivery mains, with 3.6km of main installed by the end 1914. Work commenced on the construction of the new pump pit and pump engine foundations, but delivery of the two new James Simpson & Co engines was delayed by the impact of the First World War in Europe.

Very good progress was made in 1915, allowing impounding of water to commence during the year. In May 1915 the two culverts were permanently closed with masonry and concrete, with the washout valve closed in September 1915 allowing impounding to begin. With the completion of laying the new water main, pumping from the new reservoir using the existing pumps, commenced on the 22nd October. By November, 1915 the partially completed dam held 57 million gallons and by the end of the year 85.75 million gallons had been pumped into the existing water distribution network.

The pumping equipment from James Simpson & Co arrived during the year, along with a representative Mr Daniel Dyer on the 27th March, 1915 to supervise the installation. By the end of the 1915 the boilers, superheaters and Green’s fuel economiser had been assembled and work had commenced on the first pumping engine.

Erection of the two new pumping engines continued throughout 1916 with the first unit ready for testing by the end of year. Construction of the dam proceeded smoothly and by the end of the year 211 million gallons were impounded.

Construction of the dam and associated works were substantially complete by the 21st October, 1917[iv], creating a reservoir of 1,420 million gallons for a total cost of $2,455,000.

The main dam was 382m wide with a maximum height of 52m, the base was up to 35m wide with a 5m wide road across the top. Excavation for the dam required the removal of 48,000m3 of soft material and 18,000m3 of rock. The dam construction utilised 100,000m3 of concrete, faced with 8,700m3 of locally sourced granite stone.

Works Completion

To mark the completion of the works, a memorial stone was laid by the Governor Sir Henry May on the 2nd February 1918.

The Director of Public Works, Mr Chatham noted that even with the outstanding catchwaters, the new reservoir would only meet the “ever-growing demand for water for a period of about 15 years”. He also noted that during the course of the works only two deaths were reported.

The Governor took the occasion to remind everyone on the dangers of alcohol, “I say that out of every two men who arrive here, whether as policeman, overseers on works like this, as sanitary inspector or as revenue officers, not more than one lives or remains in the service to earn a pension.”[v]

Pumping Engine Problems

It would seem that although Mr Dyer had seen the erection of the two new pumping engines, he had limited experience in commissioning of such units, possibly not helped by deteriorating health[vi]. In July 1917 Mr Jaffe wrote to Mr Dyer requesting confirmation of a date for the commissioning trials. By September, 1917 no date had been set and Mr Dyer had stopped responding to correspondence. During a later interview, Mr Dyer attributed the failure to respond to the requests due to ill health and the need to take a few days holiday in Macau to recuperate.

By October, 1917 Mr Dyer had still not committed to a date to commission the new engines. On the 26th October, 1917 the Crown Agents in frustration sent a telegram to the supplier to urgently address the problem. Mr Norman, the Shanghai agent for Messrs Simpson was dispatched and arrived in Hong Kong on the 3rd November, 1917.

Mr Norman made arrangements to undertake the commissioning test but discovered a number of problems with the engines. On the 28th November, 1917 he reported that:

– a steam jacket of the intermediate pressure cylinder was badly cracked and needed to be replaced;

– a low pressure cylinder was slightly cracked; and

– one of the steam valves was damaged.

By moving components around, Mr Norman was able to commission one of the pumping engines before the end of the 1917 while the second awaited components from England. Throughout this period the two original Tangye engines, erected ten years earlier were utilisied to transfer the water from the new dam, clocking a total of 249 days in 1917[vii]. The repairs to the broken engine were completed in the spring of 1919, but on the 25th December, 1919 the base casting of the other new engine cracked. This was rapidly repaired and all pumps were operational for 1920, the first year since 1908 when a continuous water supply was provided throughout the year.

In 1921 it was decided that a fifth pump was required. An initial proposal using a steam pump was deemed too expensive, thus an alternative proposal using electrically driven pumps was recommended to the Crown Agents. Following a further review and reduction in the price of steam equipment, that was later selected in 1922 with an order to Messes Worthington-Simpson for a new three million gallon pumping unit and boiler in the following year. Work on extending the pump house commenced in November, 1924 and was completed in December 1925. The new equipment arrived in February 1925 and erection of the engine commenced in April, 1925. Progress was slow due to labour disputes and other causes. Along with the pumping engine, new 760mm delivery pipes were installed but on the 5th September 1925 while testing, the pipe burst inundating the whole pumping station with water. Pumping resumed on the 20th September, 1925 and the new pump was commissioned on the 23rd November, 1926[viii].

The two original Tangye engines, installed in 1904 required extensive maintenance and were deemed unserviceable in 1938[ix]. They were decommissioned and disposed of in May 1939[x] to be replaced by two electrically driven centrifugal pumps.

The three Worthington-Simpson steam driven engines remained in service until September 1952 when they were decommissioned and removed, to be replaced by one new electrically driven pump and three diesel engine driven pumps.

In 1917, Tytam Tuk Dam was finished—the largest dam and reservoir in the territory. At the opening of this dam, it was publicly recognised that this new structure would only meet the demands of the Colony for the next 15 years. By 1929, with a higher than expected growth in demand, within 12 years Hong Kong Island suffered the worst water shortage of its history. A new major water source was required – it was about time to look at the Kowloon Hills and the provision of a cross harbour water pipe.

Sources

[i] Report of the Director of Public Works, For the Year 1907

[ii] Report of the Director of Public Works, For the Year 1912

[iii] Report of the Director of Public Works, For the Year 1913

[iv] Report of the Director of Public Works, For the Year 1917

[v] The China Mail, 4th Feb 1918

[vi] Tai Tam Tuk Pumping Machinery, Statement regarding engines supplied by Messrs Simpson & Co. London, W Chatham 29 May 1918 (CO129 448)

[vii] Report of the Director of Public Works, For the Year 1917

[viii] Report of the Director of Public Works, For the Year 1926

[ix] Report of the Director of Public Works, For the Year 1938

[x] Report of the Director of Public Works, For the Year 1939

This article was first posted on 4th January 2020.

Related Indhhk articles:

- Hong Kong Water Supply – The Tai Tam Tuk Scheme First Section

- Hong Kong Water Supply – The Politics of Water Supply and Rider Main Districts (1890-1903)

- Hong Kong Water Supply – Kowloon Reservoir

- Hong Kong Water Supply – Tai Tam Upper Dam (formally Tytam Reservoir)

- Hong Kong Water Supply – Kowloon Peninsula

- Hong Kong Water Supply – Pok Fu Lam Reservoir

- Hong Kong Water Supply – Mint Dam and Other Early Structures

Our Index contains many other articles about Hong Kong reservoirs.