Fung Keong (馮强, 1891-1973) – King of Rubber Shoes

By York Lo

For almost half a century stretching from the 1920s to the 1960s, the most popular casual footwear brand in Asia was Fung Keong (馮強). First manufactured in Canton in 1920, and later in Hong Kong and Malaysia, Fung Keong rubber sole canvas shoes had massive appeal during those years of economic hardship due to its affordability and are permanently etched in the collective memory of those who grew up in Hong Kong and Southeast Asia during that era. However, little has been written about the man behind the shoes – Mr. Fung Keong, who first made his fortune in Malaysia, built a multinational business empire and died in Hong Kong which is also his final resting place.

The only written bio of Fung Keong the author has located is a 4 page excerpt from the privately circulated Wan Fou County Records(雲浮縣志), a publication about Wan Fou (雲浮, Cantonese prounciaton, Yunfu in Mandarin), the relative obscure prefecture in western Guangdong province which Fung hailed from and published by Kiu Kong Wan Fou Club (僑港雲浮會所有限公司), the hometown association in Hong Kong which he also served as permanent chairman for decades. His alias were Fung Poi-fong (馮培峰) and Fung Kwok Kee (馮國基). According to the short bio, he migrated from Wan Fou to Seremban in West Malaya (now Malaysia) at the age of 11 in 1902 where he studied machinery and within a decade he made a fortune in rubber. Despite having left his homeland in a relatively young age, Fung maintained a keen interest in China and its politics and was appointed by Sun Yat-sen as the general secretary of the Seremban branch of the KMT in 1920 and vice chairman the next year.

In 1920, he returned to Canton and established a rubber factory under the name of Fung Keong Rubber Manufactory (馮強樹膠製造廠) to manufacture rubber shoes near the Hoi Chu bridge in the south side of the Pearl River. Fung Keong was not the first person to start a rubber shoe factory in Canton or China, that honor goes to Tang Fung Chi (鄧鳳墀), a lumber merchant who founded Canton Brothers Rubber (廣東兄弟) in Canton in 1919 with his ninth son Tang Siu-pang (鄧兆鵬) who returned to China from Singapore. (1) This was only few years after U.S. Rubber launched Keds, the first mass marketed canvas rubber sole shoes in the world in 1916. According to an article about the rubber industry in Canton, the period between 1920 and 1936 was the golden age for the rubber industry in Canton with over 100 factories and total output over 10 million shoes per year. Starting with only 100 workers, Fung Keong through quality products, successful marketing and innovation (such as introducing aluminium shoe lasts) has emerged as the leader of the pack with over 400 workers, daily output of 4000 pairs and as much as 9000 pairs in peak season. (2) According to the bio in Wan Fou County Records, at its peak the Canton factory employed 1500 staff.

In 1923, Fung Keong (perhaps following the footsteps of Kwangtung Bros) decided to set up a branch factory in Hong Kong. While Kwangtung Bros picked Shamshuipo for their factory site, Fung picked Shaukiwan (Shau Kei Wan) in the eastern end of Hong Kong island, the present site of Shaukiwan Centre on Factory Street. At the time both Hong Kong and Malaya (source of rubber, the raw materials for shoe production) were British colonies hence there were many advantages for Fung to establish a plant in Hong Kong. Like its Canton counterpart, the Hong Kong plant also prospered and became the largest footwear manufacturer and one of the leading industrial establishments in the colony within a decade. A report by Kung Sheung Daily News in 1928 indicated the Hong Kong plant was 20,000 square feet with 300 workers and mainly exported to Siam, Swatow, Amoy and Foochow. Most of its machineries were Chinese made and Fung Keong himself was familiar with all of them and he showed the reporter how each worked. (3) In 1933, the Hong Kong Daily Press provided a detailed account of the factory operations:

Hong Kong Daily Press (August 15, 1933)

THE FUNG KEONG RUBBER MANUFACTORY

10000 PAIRS OF SHOES TURNED OUT DAILY

SHAUKIWAN’S HIVE OF INDUSTRY

We are indebted to a correspondent for the following notes on one of the largest of Hong Kong’s manufacturing industries,the making of canvas, rubber-soled boots and shoes. This account is based on a visit to the Fung Keong Rubber Manufactory at Shaukiwan.

A BIG ESTABLISHMENT

The Fung Keong Rubber Manufactory which was established about ten years ago, has an extensive range of premises near the tram terminus at Shaukiwan. The Firm are large importers of British Empire products and employ from 1000 to 1800 prople according to the season. The rush time in the manufacture of rubber shoes is in the winter because the Chinese trade then increases considerably whereas many Chinese who wear shoes in winter go about barefoot in summer. The daily output of the factory in the busy season is 10,000 pairs, and at present 6,000 pairs. The firm has a Canton branch factory with an output of 7,000 pairs a day, but this is closed at present on account of labour problems. It will be re-opened in the near future. With the adoption of Imperial Preference, and increased tariffs in many parts of the British Empire against non-British goods, there has been a considerably increase demand in the last nine months or so from various parts of the Empire for rubber shoes produced in Hong Kong. The Straits Settlements and Federated Malay States form an important market. Hong Kong can compete with local production there because Chinese workers in the South being “strangers in a strange land” draw higher wages, just as Europeans do in the Far East.

Raw Materials The rubber for the soles comes from the Federated Malay States, canvas for the uppers from Lancashire, Shanghai or the United States of America. It has been stated in Hong Kong that Lancashire makes no equal at the price (if at all) of the Woodberry canvas manufactured in the United States of America. If Lancashire manufacturers dispute this, Hong Kong British importers will be glad to hear from them as they welcome the opportunity of giving a preference to British goods where possible. The shoe laces are made in Hong Kong and provide a large standing order for another local factory; the cyclets and binding tapes are imported from England. The cartons in which each pair of shoes is packed keep a local cardboard factory fully occupied. A visit to the shoe factory will be found of considerable interest. The place is veritable hive of industry and mass production methods are resorted to various groups of workers performing one process only and thereby developing remarkable skill. Each worker applies an identification mark to his or her output, so that if the finished product develops a particular defect the worker responsible can be identified. The workers are employed for the most part on piece work term. The hours the factory is open are from 7am to mid-day and from 1pm to 6 pm.

Crepe rubber Crepe rubber is imported from the Federated Malay States in thin sheets: it is worked up with various chemicals between hot rollers until it becomes of a texture suitable for the soles of shoes. The crepe effect on the underside of the sole is quite simply produced by having one roller with a roughened surface and the other smooth. The soles are cut out from the sheers of rubber in a manner very similar to the way a pastry cook cuts tarts from piecrust. The rubber is of such an enduring nature that the soles always outlast the shoes. In other parts of the factory rolls of canvas are fed between rollers and glued together with paste made of flour and water treated with formaling as an additional precaution against “Hong Kong foot”. When two rolls of canvas have thus been glued into one, the pieces are stretched out on tables and women supplied with pencils and stencils sketch like lightning the various parts of the uppers of shoes. The rolls are then passed on to other women workers who cut out the material along the stenciled lines. Elsewhere, binding tapes are prepared. The process of binding theupper and inner soles together by a band of tape is known as “foxing”.

Vulcanizing The factory requires a large number of aluminium shoe lasts because the sole lining, toe-cap and upper of each shoe is assembled on a model last and is finally welded into a satisfactory whole by being placed still on its last, in a vulcanising chamber. Hundreds of shoes go into a single chamber at one time, each hanging separately from rods. They remain at a temperature of 120 degrees Fahrenheit for 45 minutes. The apparatus is fitted with an automatic safety valve and a gauge to prevent the brai from rising too high or falling too low. The heat does not affect the canvas, and the result of the vulcanising is that the shoes stand up against wear is a way which they would not do if merely stuck together with rubber solution. Motorists and cyclists will appreciate the difference between hand repair of a rubber tube and the vulcanizing of the patch.

The Factory Plant The factory plant includes a 130 horse power electric motor, five additional smaller motors and two crude oil engines. Steam passes through all rollers dealing with crude rubber. Dozens of specially built Singer Sewing machines, electrically drives, perform the sewing operations at lightning speed. The factory has its own repair plant. The cases in which the crude rubber arrives from the Federated Malay States are converted on the premise into export cases by the factory’s carpentry department. All day long, men specially engaged from Shanghai make the lasts. The aluminium similar to the metal used in the linotype machine, cools rapidly and the lasts are completed at great speed. In order to meet the demands of the plant one hundred lasts have to be made of each of the 24 sizes of each pattern of shoes, and the result is that there are at the moment on the premise approximately 225,000 pairs of lasts. In the factory office are hundreds of pairs of “reference samples” representing orders which have been filled in times past which can be repeated if necessary.One of the trials of the business one gathered, is that customers frequently ask for “something different” from stock pattern for instance, the toe decoration of the model and the strap fastening of another. Or they want six eyelet holes or four eyelet holes, instead of two. Sometimes what seems like a trifling request from the customers involve expensive adaptation of machineries. Large stock of up to 250,000 pairs The total output of the factory is booked up for many months to come.

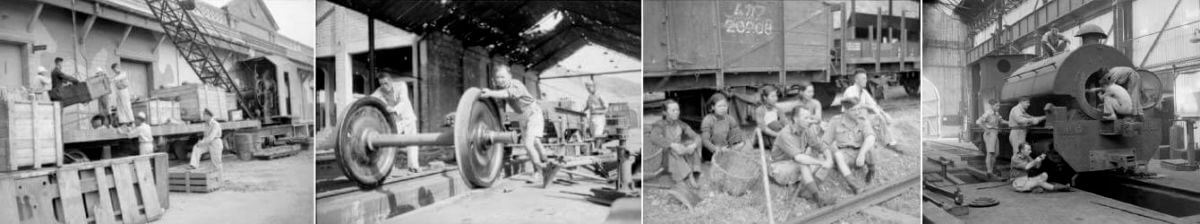

THe Fung Keong Plant, Shau Kei Wan, 1957, Courtesy: HKU Libraries and York Lo

On December 21 st , 1934, Hong Kong Governor Sir William Peel accompanied by Secretary of Chinese Affairs N.L. Smith and Inspector of Factories F. Meade visited the Fung Keong factory in Shaukiwan. (4) According to the Hong Kong Daily Press, the Governor visited twenty odds departments of the factory from raw materials to finished shoes and was “delighted”. The visit must have been one of the proudest moments in Fung Keong’s life as the event was specifically highlighted and the picture was reprinted in his bio in the Wan Fou County Records. The HK Daily Press article mentioned that “its products, which consist of a few hundred styles of shoes are exported in large quantities both to China and to foreign countries, and the business has since been very flourishing and prosperous”. It further adds that “this is the result of Mr Fung Keong’s many years experience and study acquired from abroad. It is not very much affected by the present depression on account of the recognised superior quality of its products and the various markets acquired, and also backed by a sound financial standing”. At that point Fung Keong Rubber was an unlimited company with Fung Keong as its sole owner.

First row left to right: F. Meade (inspector of Factories), Fung Keong, Governor Peel, N. L. Smith (Secretary for Chinese Affairs), Ngan Shing Kwan (顏成坤 Chairman, China Motor Bus), Ignatius Tang (manager of Fung Keong Canton factory); Second row left to right: Mr Au Kai-ming (歐啟明), Mr. Fok Kam-shek (霍金石), Mr. Fung Che-yee, Mr. Pang Kam-wing(彭錦榮), Mr. Fung Yat-hing (馮日興)and Mr. Tang Chi-nam (鄧子楠).

Source: Wan Fou County Records

While Fung Keong Rubber’s number one product was its Pagoda brand (寶塔) canvas rubber sole shoes (although most people refer to them as “Fung Keong shoes”), it also manufactured tires for bicycles and automobiles and other rubber goods such as gas masks. With his rubber profits, Fung diversified into other businesses in the 1930s by investing in the New Asia Hotel and Ka Wah Savings Bank in Canton and Hong Kong (these two enterprises were founded by Chinese Baptists affiliated with the Pui Ching Middle School) and China Motor Bus in Hong Kong (whose founder Ngan Shing-kwang was present in the 1934 Governor’s visit to the Fung Keong plant). Fung was also active in philanthropy, particularly in his hometown of Wan Fou where he donated hospitals and roads and founded the Fung Keong School in 1932 (with his younger brother Fung Kwok-sau as principal) which exist to the present day.

In 1938 the Japanese invaded Canton and Fung decided to relocate the entire Canton factory (staff and equipment) to Klang in Selangor, Malaysia and incorporated Fung Keong Rubber Manufactory (Malaysia) in 1939. After the War, Fung Keong resumed production in Hong Kong and as refugees poured in from the mainland in 1949, he hired many of them as workers including many from his native village of Wan Fou. The late 1940s and early 1950s was a difficult period for Fung Keong and the rubber shoe industry. The Communist takeover in 1949 represented the loss of a significant export market for Fung Keong but the competition remains intense with over 50 rubber shoe factories in Hong Kong. At the same time rubber prices skyrocketed due to the Korean War and for four months starting August 9 th 1950 until January 1 st 1951, Fung Keong suspended production in his Hong Kong plant as production losses exceeded thousands of Hong Kong dollars per day. (5) A 1952 survey of the Fung Keong by Wah Kiu Yat Po showed that the factory had around 1500 workers (earning daily wage of HK$6-7) in its 100,000 square feet plant and the firm was capitalized at HK$2 million. Times were tough as daily output was only 6,000-7,000 pairs, a far cry from its peak daily production of 30,000-40,000 pairs but Fung Keong still weathered the storm better than most given its scale and special privilege as one of 5-6 rubber shoe manufacturers which enjoyed tariff benefits in the colony. (6)

The late 1950s and early 1960s were better times for Fung Keong where its staff number peaked at 5,000. According to Nigel Ruscoe’s Annual Hong Kong Register, the rubber industry employed 9300 workers in 183 different establishments in 1963 – of this total nearly 8000 were making rubber shoes (citing Fung Keong as the leader) and other supply the rubber soles to other local manufacturers making rubber and canvas footwear. Exports formed 90 percent of Hong Kong footwear industries and the largest category was “footwear of textile and rubber soles” aka rubber sole canvas shoes with an export value of $55,786,000 (1,882,504 pairs) which dwarfs leather shoe export 20,497,000. The biggest export market was the UK with $30,454,000 (1,075,873 pairs) followed by Canada, US amd West Germany. (7)

By mid 1960s however labor unrest plagued the factory and in August 1967, the Hong Kong factory shut down on court orders due to non-payment of debt. Although Fung Keong continued his Malaysian operation and winded down his Hong Kong operation, he chose to maintain Hong Kong as his primary residence and on February 7 th 1973, he passed away in Hong Kong Sanatorium. His funeral was held at the Hong Kong Funeral Home and he was buried in the Catholic Cemetery in Happy Valley.

According to his obituary, Fung had two wives, one son and nine daughters. His only son Fung Che-yee (馮子儀) and eldest son in law Ignatius S. W. Tang (鄧思永) both played important roles in the family business and both sadly predeceased him. Fung Chee-yee for many years was the heir apparent and served as general manager of the Hong Kong factory. Ignatius Tang married Fung Keong’s eldest daughter Magdalene Fung Yuk-ying (馮育英) in 1934 in the Catholic Cathedral in Canton in a ceremony officiated by Bishop Bonifacius Yeung. (8) The son of a custom official, Tang graduated from Saint Joseph College in Hong Kong and earned his bachelor of science in engineering from the University of Hong Kong. He worked in the Kwangtung public works department during the infrastructure boom under Governor Chen Chi-tang where he was placed in charge of roads development and was sent to Denmark in 1931. At the time of his wedding, he was working in the Sai Chuen Cement Works as an engineer. After his wedding, Fung Keong immediately recruited Tang to join the family business and handed him the reins of the Canton operations. He was later placed in charge of the Malaysia operations. One of Fung Keong’s younger daughters, Lucia Fung Yu-king (馮育堅) married Patrick Yu Shuk-siu (余叔韶, 1922-2019) – the first Chinese Crown Counsel in Hong Kong and grand doyen of the Hong Kong legal circle in 1952. In his memoir A Seventh Child and the Law, Patrick Yu recalled meeting his future wife through Ignatius Tang when he was attending Catholic Church in Malaysia during the time he was working for his uncle Yong Shook-lin (father of former Singapore Chief Justice Yong Pung-how) in 1950. The connection between the two families might have went back earlier though as there was a 1941 Federated Malay State lawsuit between Yu’s uncles Yong Joo-lin, Yong Shook-lin and Dr. Yong Loo-lin(楊潞齡) and Fung Poi-fong (alias of Fung Keong). (9)

As the Asian economies took off in the 1970s and 80s and rising consumers flocked to Western brands such as Nike and Adidas, the affordable Fung Keong shoes lost its appeal and Fung Keong Malaysia shifted its focus to manufacturing of bicycle and motorcycle tires. In 1983, General Corporation Berhad (GCB), a construction and property development group acquired Fung Keong Rubber Malaysia for SG$34.5 mil, $20 mil of which in cash and the remainder in new share issues. (10) The primary objective of the acquisition was to develop Fung Keong’s hectares of land so the shoe factory was closed down and production was moved to mainland China. On the tire front, it entered into joint venture with Inoac of Japan in 1987 and Dutch tire maker Vredstein in 1995 and today remains a leading tire manufacturer in Malaysia under the FKR brand. In the shoe front, it stopped producing sports shoes at one point to focus solely on school shoes only to bring back sports shoes in 1998. In an ironic twist, the Fung Keong shoes which were once symbols of patriotic pride in China are now marketed primarily in Malaysia under Western sounding brand names such as All America, Pennylane, FKS and Fleks. (11)

This article was first posted on 13th October 2015.

Sources and Notes:

- In the 1920s, Kwangtung Brothers was a top brand in China having established its base in Shanghai and promoted its products through celebrity endorsements. However, the firm ran into financial difficulties in 1935 and its position was overtaken by Fung Keong.

- http://www.gzzxws.gov.cn/gzws/gzws/ml/51/200809/t20080916_7558.htm

- The Kung Sheung Daily News, 1928-11-21

- “Fung Keong Rubber Manufactory: H.E. The Governor’s Visit” HK Daily Press, December 22, 1934.

- Ta Kung Pao, November 29, 1950 and January 1, 1951

- Wah Kiu Yat Po, March 12, 1952

- Nigel Ruscoe’s Annual Hong Kong Register 1964, p 111

- “Canton Ceremony: Rubber Magnate’s Daughter Married” The Straits Times, 16 April 1934, Page 17

- The Singapore Free Press, 25 February 1952, Page 8

- Singapore Monitor, 7 July 1983, Page 15

- “Fung Keong Lives….. Sort of” The Star, July 1, 2006

Related Indhhk articles:

Hi, my name is Alex.

I am the Executive Creative Director of the TAG. https://www.theactivationgroup.com.sg/

I understand you produce rubber footwear?

We are interested to work with you on producing Rubber school shoes for children.

Can we arrange for a video (google meet, whatsapp) call, please?

I can explain further.

Thank you. Looking forward to speaking with you urgently.

Best regards,

Alex lim

Executive Creative Director

M: +65 9685 7620

THE ACTIVATION GROUP PTE LTD

2 Alexandra Road, Delta House #04-01

Singapore 159919

T +65 6536-3283

http://www.theactivation.group

small bio on Fung Keong from 1973

https://eresources.nlb.gov.sg/newspapers/digitised/article/stannual19730101-1.2.15.1?qt=fung,%20keong,%20rubber&q=FUNG%20keong%20rubber